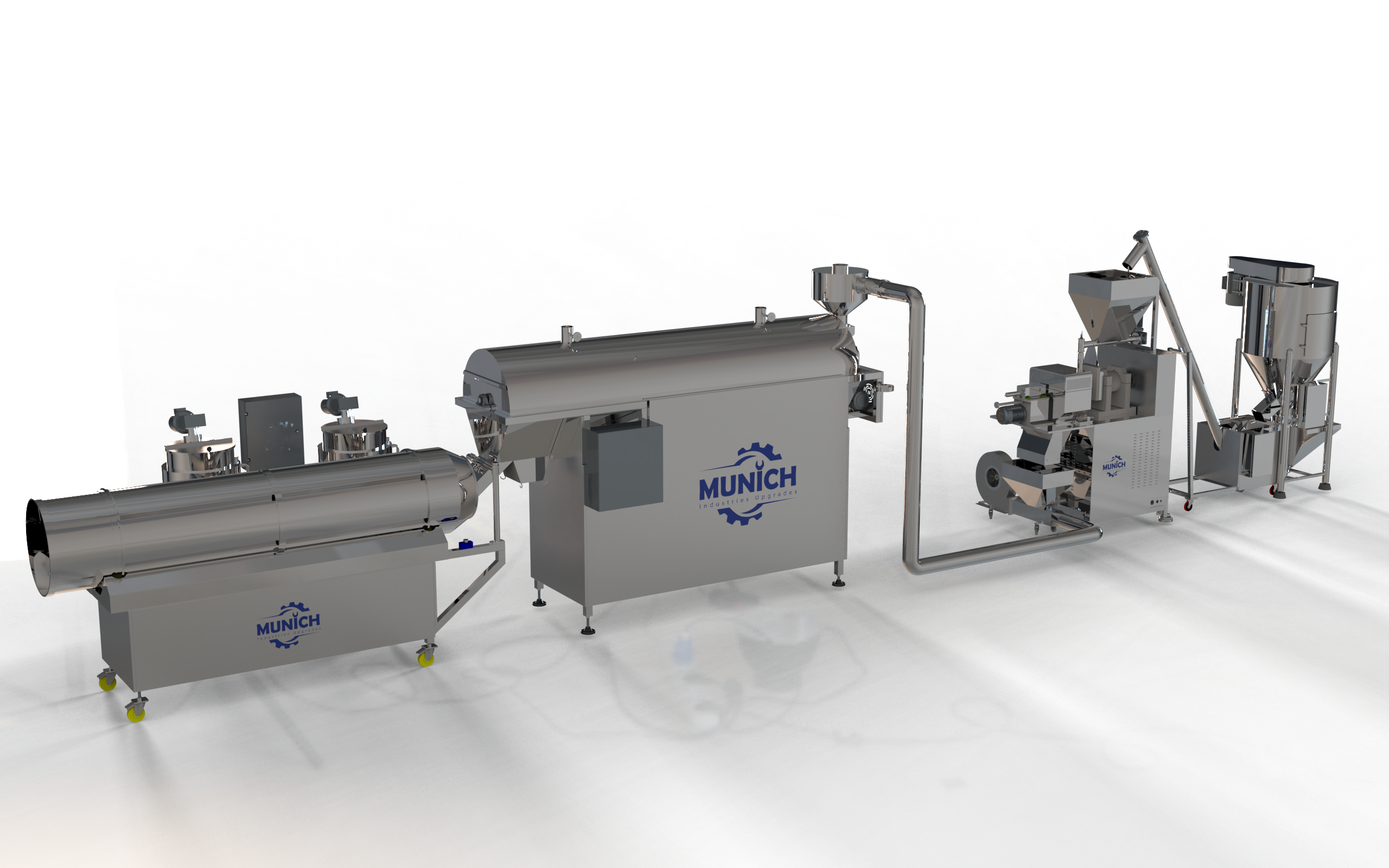

corn mixer

Corn Mixer

Capacity: 300 kilograms

Construction Material: Manufactured from food-grade stainless steel 304, providing corrosion resistance.

Level Indication: Equipped with an inspection port to visually assess the material level inside the mixer.

Discharge Mechanism: Features a calibrated discharge gate for controlled emptying of the mixed material.

Mechanical Safety Guarding: Fitted with a mechanical guard (metal mesh) to prevent operator hand entry into the mixer.

Electrical Safety Provision: Prepared for the addition of electrical safety interlocks to protect personnel during cleaning procedures.

Metallic Impurity Removal: Incorporated with a mechanism for the extraction of any metallic contaminants potentially present within the corn.

Humidification System: Includes a 2 kW water tank for material humidification.

Main Drive Motor Power: Equipped with a 4 horsepower (HP) main drive motor.

Control Panel: Features a complete control panel housing all control systems and electrical protection mechanisms.

Screw Conveyor (Corn Transfer)

Functionality: Designed for the automated feeding of material into the extruder.

Mechanical Safety Guarding: Equipped with a mechanical guard to prevent operator hand entry into the conveyor mechanism.

Metallic Impurity Removal: Features a magnetic system for the extraction of any metallic contaminants potentially present within the corn.

Motor Specifications: Powered by an Italian or Turkish motor with a power rating of 0.75 kW.

Construction Material: Manufactured from food-grade stainless steel 304.

Height: Has an overall height of 300 centimeters.

Hopper Capacity: Includes a hopper with a capacity of 75 kilograms.

Cleaning Feature: Fitted with a bottom access port for ease of cleaning.

Integrated Production Extruder

Function: The extruder is responsible for dough forming and the production of Cheetos-type snack pellets.

Production Capacity: Output capacity ranges from 170 to 200 kilograms per hour (kg/h), depending on the desired pellet shape.

Insulation and Cladding: Fully insulated and clad with an external layer of food-grade stainless steel 304 for ease of cleaning.

Feeding Screw: Equipped with a product feeding screw manufactured from corrosion-resistant food-grade stainless steel 304. The main screw speed is designed for continuous operation during extended working hours.

Fault Diagnostics: The production line is programmed with an automatic fault detection system that displays error messages on the screen.

Motor Power: Powered by a motor with a power rating of 35.5 kW.

Air Blower Lifting System (Air Feeder)

Function: An air-powered feeding blower designed to elevate snack products to the oven, functioning as a conveyor for transferring material from the lower section of the extruder to the oven.

Power Rating: Rated at 2 kW.

Construction Material: Manufactured from corrosion-resistant food-grade stainless steel 304.

Installation and Maintenance: Features a design for easy installation and cleaning.

Rotary Drying Oven

Construction: Composed of a cylindrical drum manufactured from chrome/stainless steel.

Heating System: The rotary drying oven operates using electric heating elements.

Insulation: Enclosed with a double-layered stainless steel casing with thermal insulation between the layers to minimize heat loss for optimal energy efficiency.

Debris Removal: Equipped with a mechanism for the expulsion of any debris that may result from the rotation of the oven and product friction.

Motor Specifications: Powered by a 1 horsepower (HP) motor, of Turkish origin.

Length: Has an overall length of 4.5 meters.

Temperature Range: Capable of reaching temperatures up to 300 degrees Celsius.

Flavoring Mixer

Construction: Composed of a chrome tank with a motor and gearbox assembly terminating in a vertical screw agitator.

Construction Material: Manufactured from food-grade stainless steel 304.

Outer Diameter: Has an external diameter of 85 centimeters.

Motor Specifications: Powered by a 2 horsepower (HP) motor, of Italian or Turkish origin.

Agitator Design: The agitator blades are specifically designed to prevent the accumulation and clumping of flavoring powder.

Discharge Port: Equipped with a chrome cover at the material discharge end, designed for easy opening and closing to facilitate cleaning procedures.

Mobility: Fitted with wheels for ease of movement and cleaning.

Powder Flow Control: Features an inverter for controlling the quantity of powder flowing to the subsequent flavoring drum.

Liquid Flavoring Tanks (7 Flavors)

Construction Material: Entirely manufactured from corrosion-resistant food-grade stainless steel 304.

Frame Length: The frame has a length of 3 meters.

Inverter Equipped: Features an integrated inverter.

Motor and Gearbox: Equipped with a % horsepower motor with a gearbox for speed control.

Discharge Port Closure: Also features a near-complete closure at the material discharge end to prevent the loss of flavoring powder.

Electrical Power Rating: 75 kW.