Munich Production Lines: Engineered for Excellence.

Precision-engineered production lines from Munich, delivering reliable performance and exceptional quality for your manufacturing needs.

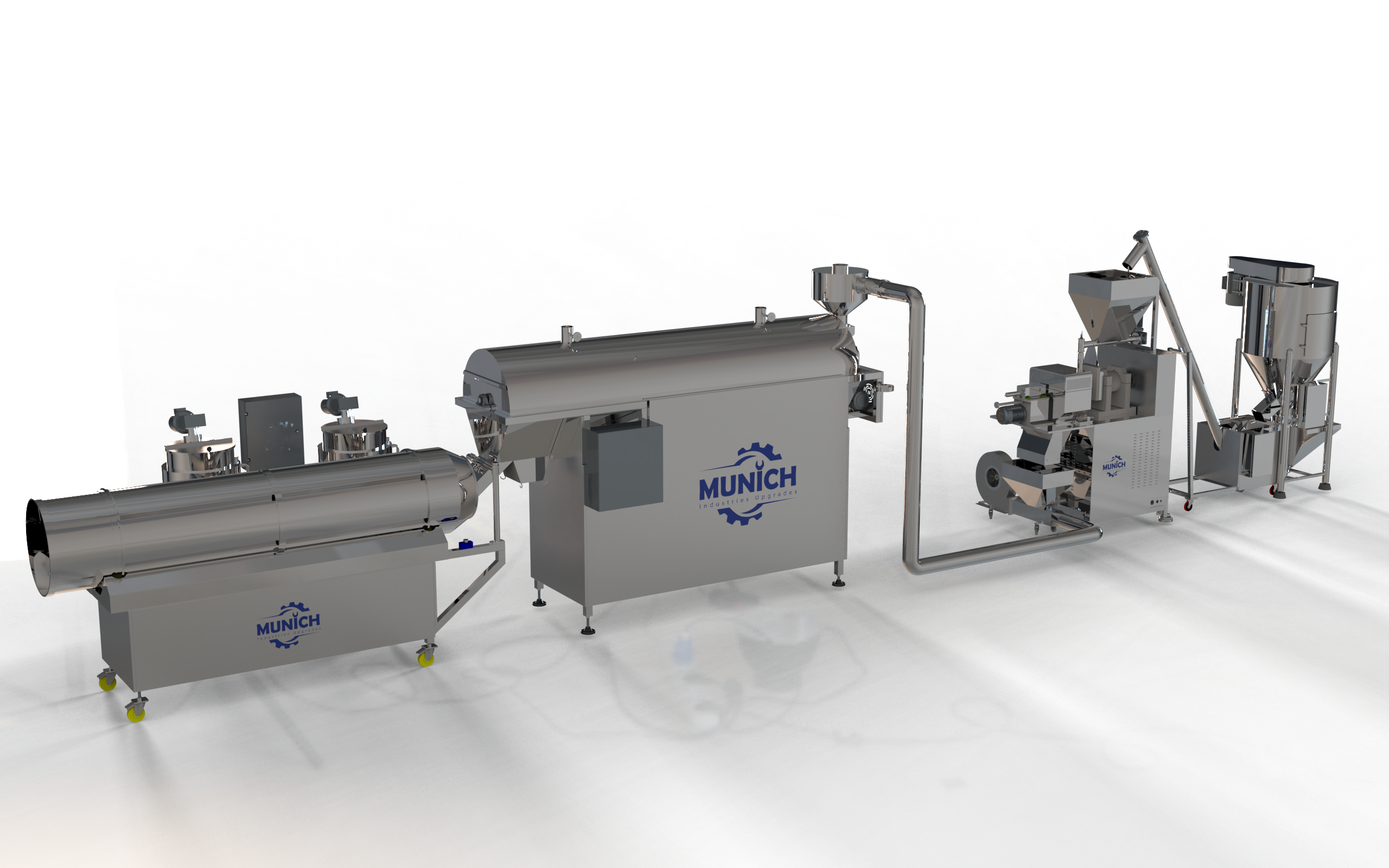

Snacks Production Line

Production Capacity: From 250 kilograms per hour (kg/h) to 350 kilograms per hour (kg/h)

Line Components:

–Corn Mixer

-Screw

–Conveyor (Corn Transfer)

-Integrated Extruder (Production-Specific)

-Air Blower

–Conveying System

-Rotary Drying Oven

-Flavoring Mixer

-Liquid Flavoring Tanks (7 Flavors)

.

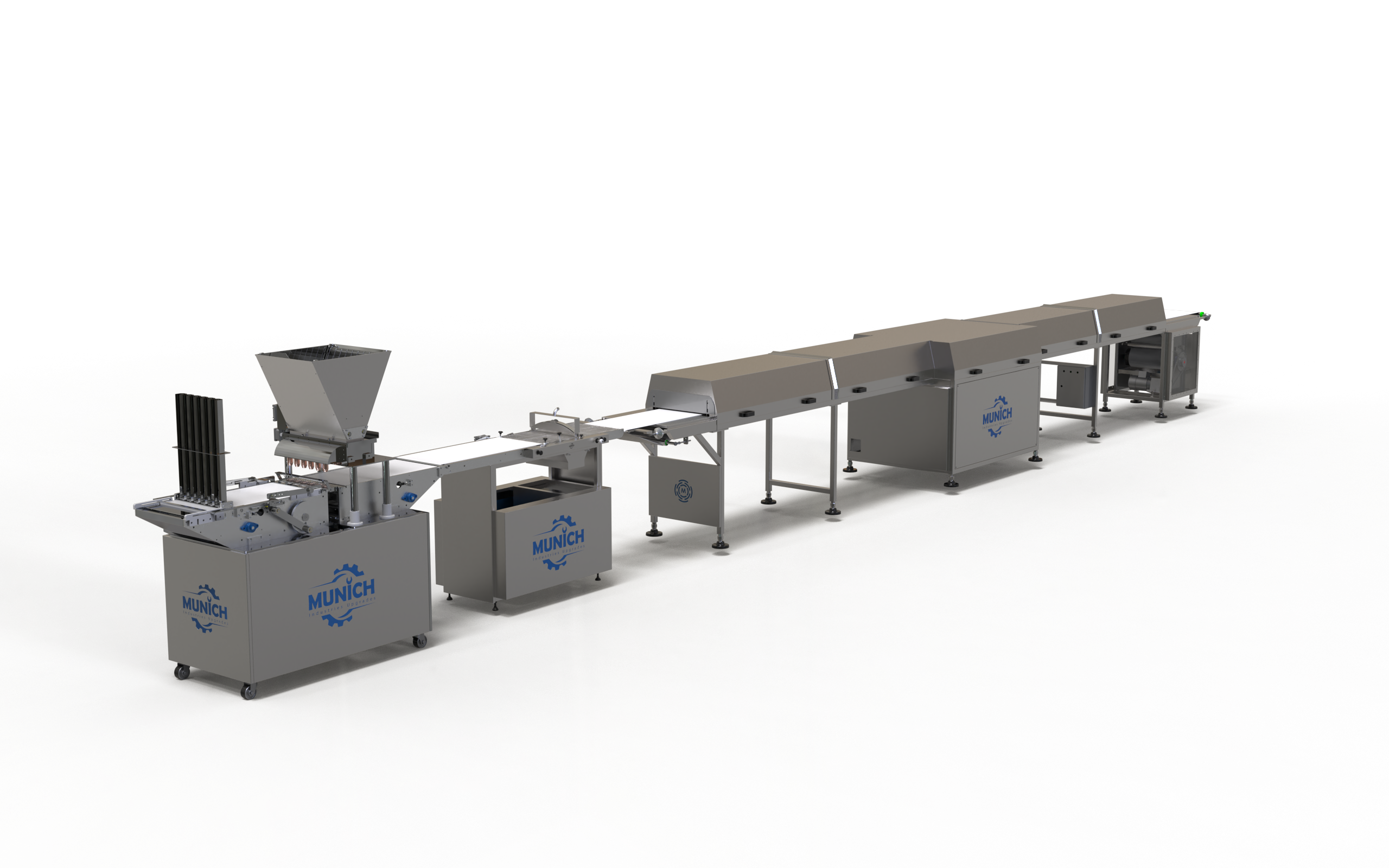

Chocolate enrobing and cooling line

Automated Chocolate Enrobing and Cooling System for Diverse Confectionery and Food Products

This advanced industrial system is specifically designed for the automated enrobing of a wide array of products, including but not limited to cakes, biscuits, dried fruits, nuts, caramel candies, and ice cream, with a consistent layer of chocolate. The system comprises two primary integrated modules: a precision chocolate enrobing machine and a high-efficiency cooling tunnel.

Module 1: Precision Chocolate Enrobing Machine

This unit is engineered for the precise and uniform application of chocolate coating onto the product stream. Key features include:

Module 2: High-Efficiency Cooling Tunnel

This module is designed for the rapid and controlled solidification of the applied chocolate coating, preserving its shape and ensuring product integrity. Key features include:

.